COMPLETE POWER QUALITY SYSTEMS

Due to the increasing use of electronics and automation systems, an ever-increasing number of electrical installations are facing power quality problems.

ELIMINATION OF HARMONICS

The increasing use of technological equipment results in the appearance of harmonics in industries, marine, hospitals, renewable energy projects, and buildings.

Equipment strains and damages, increased maintenance costs, unforeseen production outages, destruction of sensitive electronic devices, increased thermal losses, energy or fuel consumption, are only some of the most serious consequences of harmonics.

With the use of active filters, harmonics are eliminated at their creation before entering the network; as a result, the electrical installations are protected against undesired and harmful consequences.

POWER FACTOR CORRECTION

Power Factor distortions are common in the electrical networks causing energy inefficiencies, increased energy bills, and premature aging of the cables and transformers.

Our Power Factor Correction Systems reduce the “useless” inductive currents required by the loads and thus, positively impact the efficiency of the entire electric network; at the same time, they reduce the presence of harmonic currents.

To maximize the benefits, we offer all services needed, from the measurements and correct dimensioning of the system, to the continuous monitoring of its functioning (to avoid "losing power"), and the proper maintenance - in order to protect cables and transformers from unnecessary power dissipation.

VOLTAGE STABILIZATION

Voltage fluctuations cause various problems. They increase the total energy consumption, maintenance costs, and may even destroy sensitive electronic equipment or create various malfunctions (shutdowns, strains, wear, etc).

The stabilization of voltage - regardless of the inevitable fluctuations of the input of voltage - is a critical factor for the smooth operation of each electrical installation.

Depending on the needs of your application, we recommend a suitable type of voltage stabilizer, ensuring the reliability and efficiency of your electrical installations.

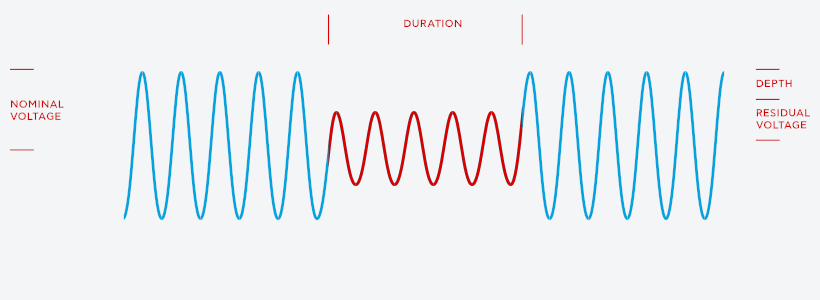

SAG COMPENSATION

More than 60% of the equipment maintenance costs to achieve power quality are caused by voltage dips and small power outages. Voltage dips (or SAGs) are the instant, long in RMS value, and short-term voltage drops.

SAGs and small power outages are the main causes of poor power quality. They burden and put the equipment (automated and electronic systems, inverters, data processing, and control equipment) at risk.

With SAG compensators, you protect your equipment against endless voltage imperfections; effectively and economically.

POWER QUALITY.

PROTECTION OF EQUIPMENT.

EFFICIENT OPERATIONS.

End-to-end high added-value services at all stages of implementation.

Measurements

High precision measurements and recording of harmonics and other electrical magnitudes; with modern calibrated and measuring instruments of high standards.

Engineering

Complete power quality engineering with the use of specialized calculation tools and models; based on international standards or special requirements from the user and application.

Supply of Equipment

Supply and installation of the equipment based on the outcomes of the engineering study and the special requirements identified.

Commissioning

Commissioning of equipment, execution of controls and tests, detection of possible installation errors, and real measurements following the activation of equipment.

Maintenance

Comprehensive maintenance program for power quality equipment executed by specialized technical staff based on detailed user and service manuals.

Technical Support

Unparalleled technical support for all our products with technical solutions and advice, use of new implementation technologies, updated measurements, test records, and provision of spare parts.

POWER QUALITY

A MULTI-DIMENSIONAL PHENOMENON

Learn more about the causes, consequences, and alternative solutions to the problems of poor power quality.