We are pleased to announce that starting Monday, September 1st, our company will officially begin operations at our new location: 70 I. Gavriil Street, Acharne.

One of the very few manufacturers globally with certified low-voltage transformers

With the use of specialized software of high precision, we design our transformers by comparing and evaluating alternative manufacturing strategies for each application.

Thus, we ensure and document the optimal quality-cost relation of our products, prior to the beginning of the production process.

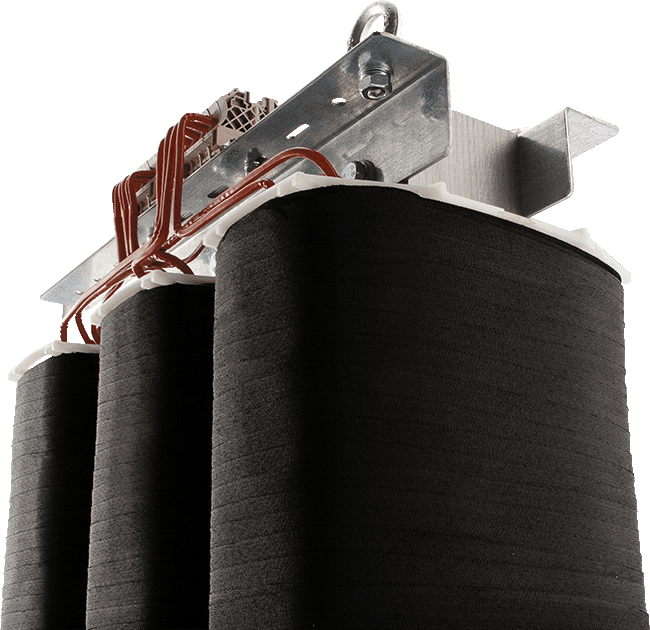

By applying innovative winding techniques, special air ducts are created between the coils ensuring the free dissipation of the heat and the low operating temperature of our transformers.

In addition, with the use of a core of low losses, energy losses are minimized up to 1%.

The combined use of top-quality raw materials reduces the requirements in terms of space and weight, while at the same time, keeps the quality of the transformers at high levels.

By applying innovative winding conductors, we eliminate the empty spaces created during the winding process.

TRANSFORMERS >150KVA

9 POINTS OF SUPERIORITY

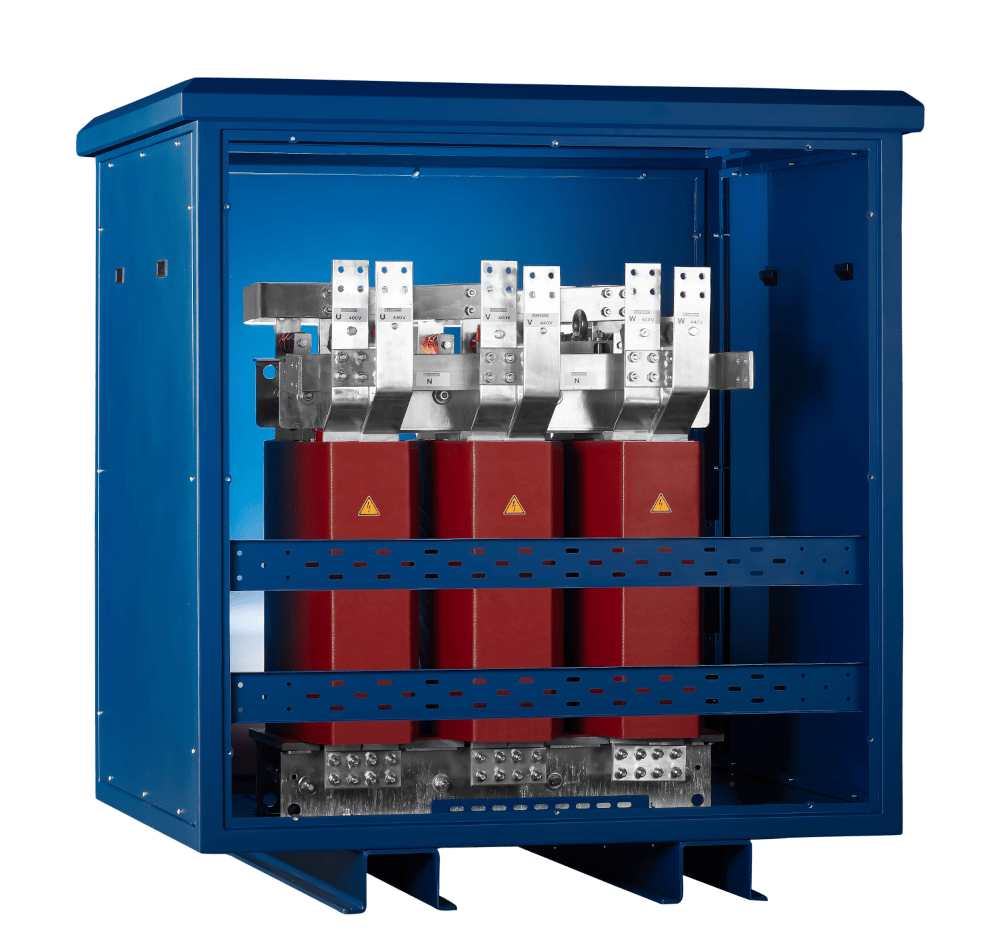

The smart design with special ventilation openings and hidden spots inside the enclosure provides a high protection level and the necessary ventilation for achieving energy saving.

The smart design provides internal air ducts in order to achieve the necessary ventilation and the low operating temperature, even during temporary load fluctuations.

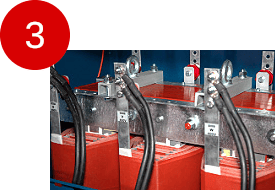

Special high-current cable terminations prevent thermal losses and enhance the performance of the transformers.

The special cable routing design with mechanical support eliminates the danger from possible current leakage and the progressing loosening.

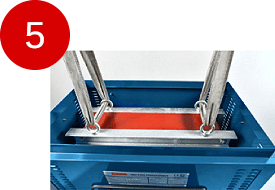

The lifting lugs on the transformer minimize the human effect during transportation and provide protection against labor (industrial) accidents, damage to equipment, or deformation of the enclosure.

The easy removal and re-positioning of the surfaces of the enclosure, provide full and convenient access, make installation easier, and reduce the required maintenance duration.

Leading-edge foil technology eliminates the gaps created during winding and minimizes the size and weight of the transformer in relation to its power.

The low operating temperatures minimize the stress on insulation material and extend the lifetime of the transformer.

The high-standards encapsulation, the special specification paint, and the special process of metallic parts for rust protection provide high endurance against hard environmental conditions (humidity, temperature) in marine applications.

Certified raw materials of top quality and insulation by branded European producers

Transformers certified, following regular inspections based on the strictest international standards

Full quality control with the strictest specifications to all final items, one by one

Written official power of the transformers correspond fully to the actual power

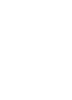

Due to the increasing use of electronics and automation systems, an ever-increasing number of electrical installations are facing power quality problems.

The increasing use of technological equipment results in the appearance of harmonics in industries, marine, hospitals, renewable energy projects, and buildings.

Equipment strains and damages, increased maintenance costs, unforeseen production outages, destruction of sensitive electronic devices, increased thermal losses, energy or fuel consumption, are only some of the most serious consequences of harmonics.

With the use of active filters, harmonics are eliminated at their creation before entering the network; as a result, the electrical installations are protected against undesired and harmful consequences.

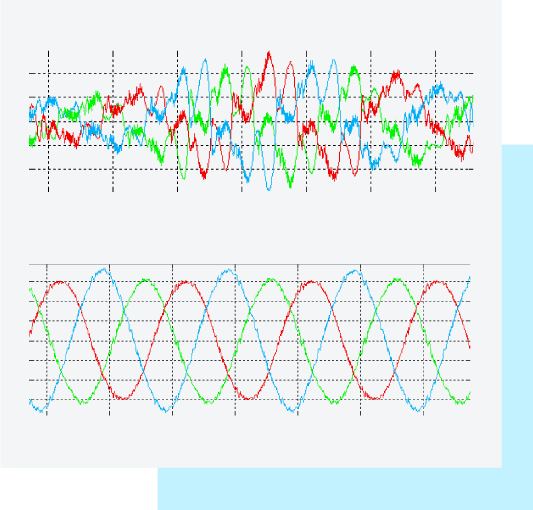

Power Factor distortions are common in the electrical networks causing energy inefficiencies, increased energy bills, and premature aging of the cables and transformers.

Our Power Factor Correction Systems reduce the “useless” inductive currents required by the loads and thus, positively impact the efficiency of the entire electric network; at the same time, they reduce the presence of harmonic currents.

To maximize the benefits, we offer all services needed, from the measurements and correct dimensioning of the system, to the continuous monitoring of its functioning (to avoid "losing power"), and the proper maintenance - in order to protect cables and transformers from unnecessary power dissipation.

Voltage fluctuations cause various problems. They increase the total energy consumption, maintenance costs, and may even destroy sensitive electronic equipment or create various malfunctions (shutdowns, strains, wear, etc).

The stabilization of voltage - regardless of the inevitable fluctuations of the input of voltage - is a critical factor for the smooth operation of each electrical installation.

Depending on the needs of your application, we recommend a suitable type of voltage stabilizer, ensuring the reliability and efficiency of your electrical installations.

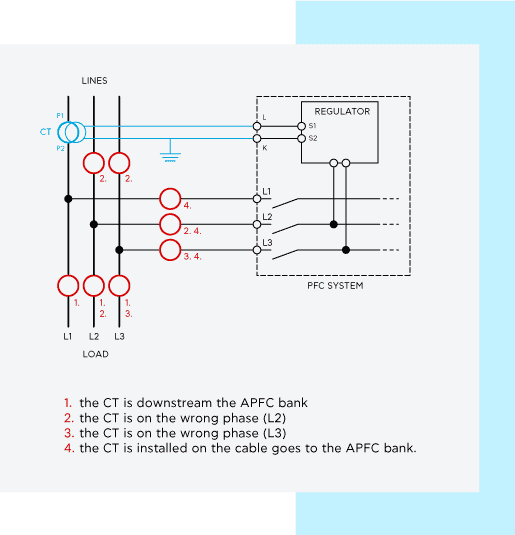

More than 60% of the equipment maintenance costs to achieve power quality are caused by voltage dips and small power outages. Voltage dips (or SAGs) are the instant, long in RMS value, and short-term voltage drops.

SAGs and small power outages are the main causes of poor power quality. They burden and put the equipment (automated and electronic systems, inverters, data processing, and control equipment) at risk.

With SAG compensators, you protect your equipment against endless voltage imperfections; effectively and economically.

End-to-end high added-value services at all stages of implementation.

High precision measurements and recording of harmonics and other electrical magnitudes; with modern calibrated and measuring instruments of high standards.

Complete power quality engineering with the use of specialized calculation tools and models; based on international standards or special requirements from the user and application.

Supply and installation of the equipment based on the outcomes of the engineering study and the special requirements identified.

Commissioning of equipment, execution of controls and tests, detection of possible installation errors, and real measurements following the activation of equipment.

Comprehensive maintenance program for power quality equipment executed by specialized technical staff based on detailed user and service manuals.

Unparalleled technical support for all our products with technical solutions and advice, use of new implementation technologies, updated measurements, test records, and provision of spare parts.

Learn more about the causes, consequences, and alternative solutions to the problems of poor power quality.

if you want to discuss your own needs

or have any questions.

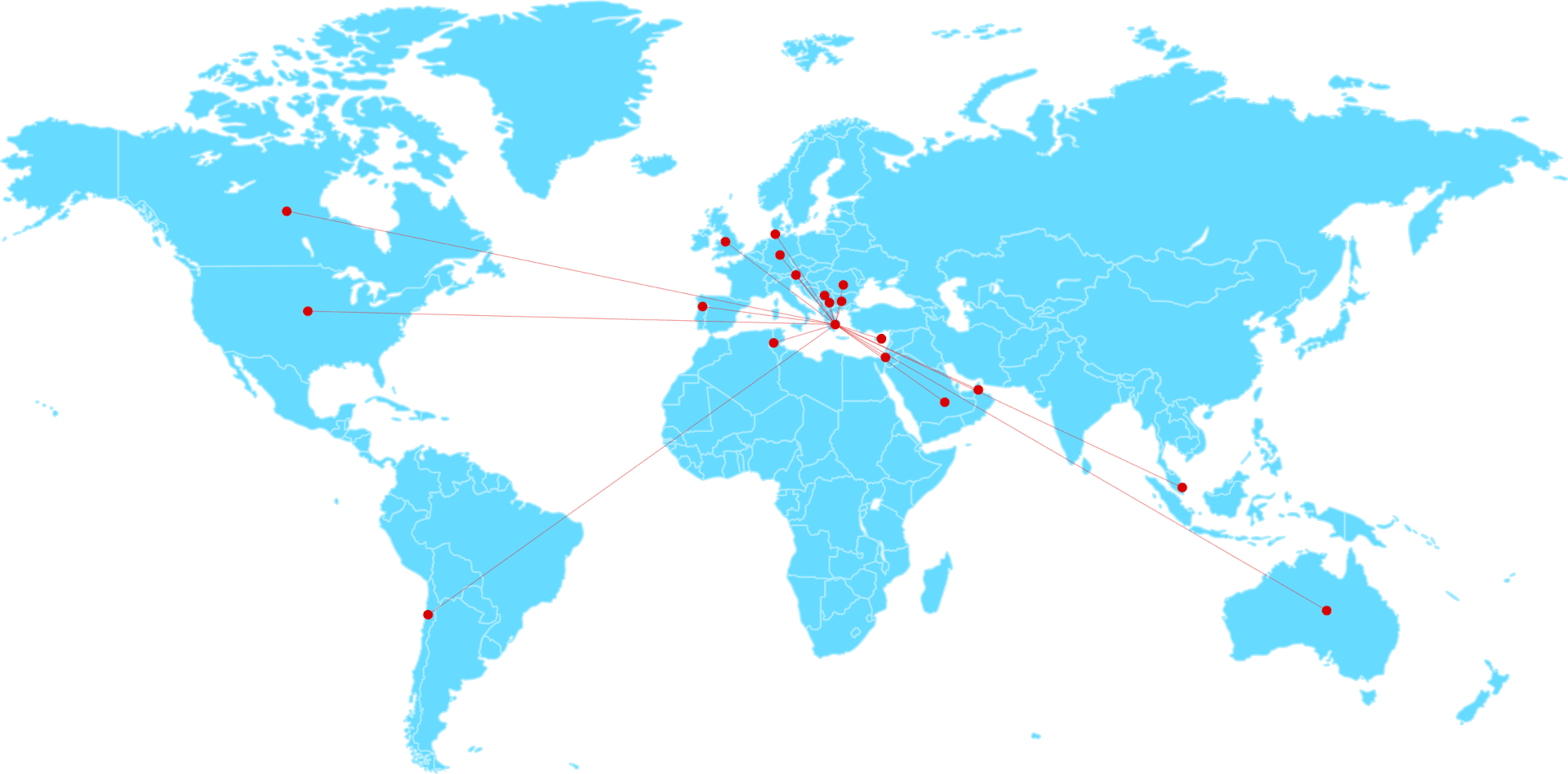

USA

Canada

Chile

UK

Portugal

Netherlands

Austria

Germany

Bulgaria

Romania

North Macedonia

Albania

Serbia

Cyprus

Israel

Dubai

S. Arabia

Singapore

Australia

Tunisia

With great interest, was completed on Saturday 4 June 2016 in EMMIS facilities, the training of National Electricians Contractors of Higher and Secondary Technical Education on “Transformers and other power and control products “.

The content of the training was designed in two (2) main parts:

The theoretical training of the participants about the operation , uses, applications, benefits and quality selection criteria of low voltage transformers , as well as a range of products that belongs in the power supply and control industry, such as voltage stabilizers, insulation monitors, temperature monitors, multifunction multimeters and network analyzers, industrial earth leakage relays and current transformers.

Live monitoring of low-voltage transformer production process – from the stage of raw materials until the completion of quality control – which strictly adheres to international standards and incorporates the corresponding expertise in manufacturing certified low-voltage transformers.

The training was delivered by the personnel of the respective EMMIS departments (Sales, Production, Quality Control & Technical Support) and lasted from 9.00am until 2.00pm.

The event was honored by the National Association of Retired Electricians which was represented by Mr. George Kissandrakis (President) and Mr. Lefteris Skaris (General Secretary).

All participants received the Seminar Confirmation of Participation.

Training of electricians - installers of the National Electrical Contractors Association of Higher and Secondary Technical Education in the EMMIS facilities